Choose Laser Cutting for Clean, Precision Cutting

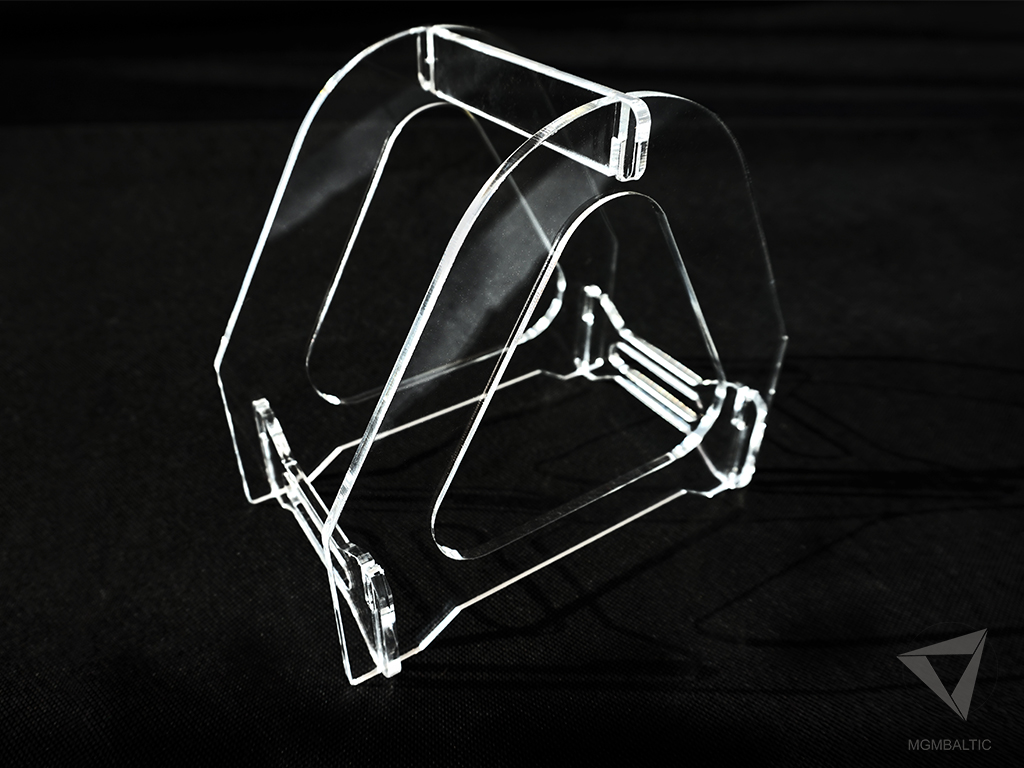

Laser-cutting technology uses a high-powered laser beam to cut various designs from different types of flat materials. MGM Baltic offers a laser cutting service for industries seeking to make small, complex parts with accuracy and precision. So read on to discover some important reasons why you should consider choosing laser cutting for your next project.

anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline anemptytextlline

anemptytextlline

Works with a range of materials

Lasers are effective design instruments which can be used to cut your material to various thicknesses. The versatility of a laser cutter allows us to cut a range of materials to suit our customers’ exact commercial needs and preferences. These include:

• Acrylic

• Cardboard

• Metal up to 3-millimetres thick

• Stainless steel up to 1-millimetre thick

• Acrylic artificial stone (Corian)

• Wood

• Die board

• Plastic

• Paper rubber

• Leather

• Double colour board

• Leather

• Glass

• Tile

High Precision

Laser-cut technology uses a small laser which is designed to deliver a focused beam to the chosen material with an unrivalled level of accuracy. It’s important to understand that the laser beam does not wear during the cutting process, because it is actually designed to melt and vaporise the material, leaving a clean edge with an unparalleled high-quality finish. The machine allows outstandingly clean and accurate cuts, ensuring the finished product has an ultra-smooth finish. This spot-on accuracy and high precision enables us to provide our customers with superbly detailed, high-quality results. In fact, this technology allows us to fully harness and control the power of the laser, which means we can then produce highly consistent results with virtually no margin of error.

Rapid, Time-Efficient Production

Lasers can move rapidly at anything from 20 up to 70 inches per minute. And one advantage is this cutting speed enables us to create complex laser cutting designs within a short period without the need for reworking or having to sacrifice the quality of the work. The material is not clamped during the cutting process, which thus saves time on fixture as well as cutting out any auxiliary loading and unloading. This naturally leads to faster production runs, which saves customers time because the entire process involves fewer steps. Laser-cutting technology is therefore an ideal method for producing both large and small-scale quantities of the same product.

Designs can be Tailored to Fit Your Needs and Preferences

Laser-cut machines incorporate software programs which allows for more creativity in the development of laser cutting ideas for products. Our control software gives you freedom to choose the graphic design files you want to use for laser processing. Whether your design is simple or complex, our machines will be able to process it. This makes the process suitable for those looking to secure a unique engraved logo for their business identity. Our team will help you choose the right material to match and enhance your design template.

Flexibility

Conventional cutting techniques are relatively inflexible and therefore don’t allow you to make changes or modifications in the manufacturing process. Laser-cutting technology, on the other hand, allows you to benefit from complete flexibility within the production process. Up to the moment the laser process starts, you can make any changes or adjustments which may be required to suit your preferences and create the outcome you envisage.

Offers a Cost-Effective Way to Cut and Engrave Materials

Laser cutting works by directing the laser output via optical control, so there is absolutely no need for external tools to sharpen or cut holes in your material. And because the process requires no hand tools, there’s also no need for tool sharpening, changeover or specialist storage demands. As a laser cutting company, this allows us to troubleshoot on the fly and quickly reprogram prototypes to overcome potential production issues with absolute ease. The accuracy of the machine also means that there is no wastage of materials. For these reasons, we are able to offer affordable laser cutting and engraving services to our customers.

No Signs of Warping or Damage

When cutting materials via traditional methods, the surfaces of the moulded part won’t always follow the expected design shape. Residual stresses can cause warping of parts, often the result of what is known as differential shrinkage. Rectifying these kinds of defect may cost you time and money. However, using laser-cut processing the workpiece material cannot bend or twist out of shape during manufacturing. Parts will have clean edges which are smooth to the touch and will be ready at once for the next process. This cost efficiency means there is no need for any post-cut finishing.

Automated Process

A laser cutting machine is run by computer numerical control. The machine follows a programmed instruction to process materials to exactly meet the specification, ensuring that the parts and products created are all identical. This reduces the need for further reworking and makes for more consistent workflows with fewer flaws.

Reduced Workpiece Contamination

Using feedstock material which contains contaminants invariably leads to a lower-quality finished product. Laser cutting processing offers less workpiece contamination because there is no cutting edge to contaminate the material or accumulate waste products from the workpiece material. This results in a high-quality finished product.

Non-Contact Cutting

Laser cutting is an entirely non-contact process, meaning the laser beam has no physical contact with the material being cut. Instead, it uses heat to melt and cut the workpiece. This helps prevent damage to the work material and also reduces the risk of distortion. And as a result, allows us to perform much more intricate cutting and shaping.

Allows for Narrower Kerf Widths

The focused beam of a laser cutting machine allows for narrower kerf widths. This helps to minimise the amount of material removed in the cutting process. A narrow kerf also allows us to set up nest cut patterns in relatively close proximity. In turn, this helps to reduce or eliminate scrap during the production process and thus promotes greater efficiency.

Generates a Smaller Heat-Affected Zone (HAZ)

The heat-affected zone is the unmelted area of the base material whose mechanical properties are affected by heat during the cutting process. The laser cutting process has a high rate of heat input, yet cools faster, resulting in a smaller HAZ. The heat-affected zone causes structural changes in the material, potentially weakening this area of the part. A smaller heat-affected zone helps alleviate HAZ-related issues, such as surface cracking, thermal distortion and embrittlement.

Allows Us to Laser-Cut Outstanding Business Cards

Business cards are an effective tool for generating customers. You can use them to stand out and beat the competition. Laser cutting allows you to turn your business cards into an impressive design statement. You can use your company logo or design another pattern of your choice. A striking business card design will attract the attention of prospective customers by giving your card an ultra-professional look which will create a favourable impression of your business.

Create Laser-Cut Signs to Make Businesses More Visible

Exterior laser-cut signs are an important component of your business marketing strategy. Laser cutting signs with your company logo can help differentiate your business from others in the same location. And by attracting attention, they can also act as a salesperson for your business. When added to a special display, creative interior signs can advertise promotions and help your customers locate items, leading to increased sales. So why not search for ‘laser cutting near me’ right now?

MGM Baltic provides laser cutting services to help you advertise and grow your business. We would love to help you meet your business goals. Feel free to contact us today for more information about our services.

English

English Dansk

Dansk